Tailstock lock improvement

The original tailstock lock on my mini lathe left a lot to be desired. It consisted of a threaded rod carelessly welded to a square piece of steel that clamped against the underside of the lathe bed. The rod protruded up through the tailstock casting and was secured with an M10x1.5 nut and a washer. The metal square on the bottom of the rod was crooked and the top surface of the tailstock casting that the nut tightened against wasn’t flat either. Finally, the hole that the rod passed through was much wider than the rod itself, so it was easy for the rod to be tilted as you were tightening the nut. All these things made the tailstock lock feel sloppy, mushy and imprecise. Sometimes the tailstock would move as you were tightening it and sometimes tightening the nut just wouldn’t hold the tailstock securely.

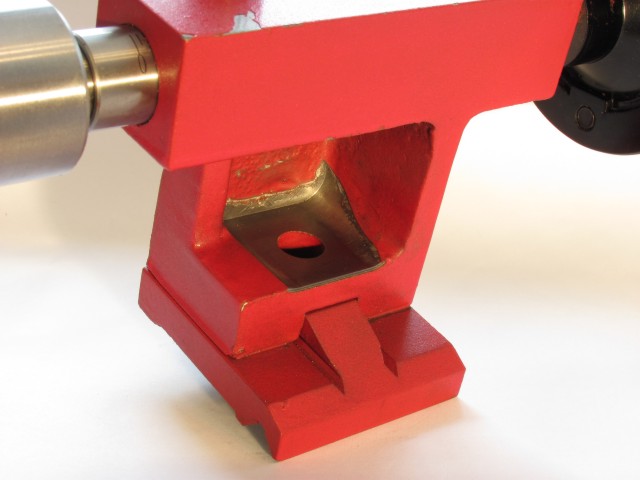

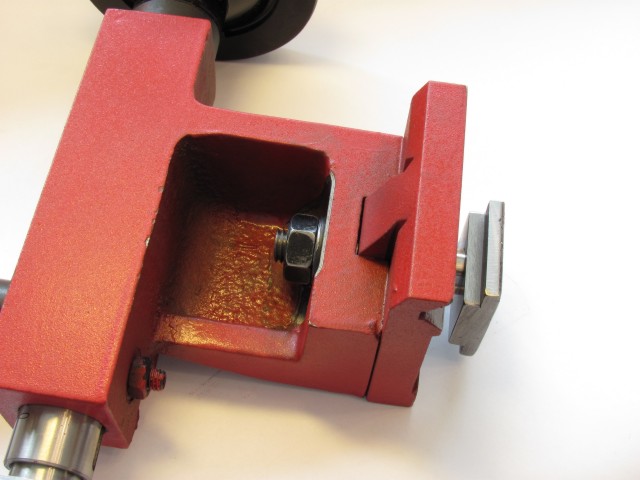

To solve this problem, I made a 0.5" diameter rod which threaded into a thicker, more precisely cut bottom piece with a shoulder milled in it to keep it from twisting as you slide the tailstock along the lathe bed. On the tailstock itself, I milled a flat surface for the nut and washer to bear against. I realize there are lots of lever-actuated tailstock lock designs out there, but I was more concerned with just making the original design work properly by correcting the deficiencies. I keep a nice 17mm box-end combination wrench within easy reach from the lathe, so I haven’t been bothered much by tightening the nut to lock the tailstock. Besides, the new parts are so much more rigid and precise that it only takes about an eighth of a turn of the wrench to lock it in place.

Now that the vertical steel rod almost completely fills the hole running through the tailstock, I can’t offset the tailstock any more. If I want to have this functionality in the future, I’ll have to either put the original piece of junk back in, or mill an elongated hole in the tailstock casting. Mind you, I’ve never needed to offset my tailstock in the many years I’ve owned my lathe, so I’m not too worried about this.

I basically figured things out as I went along with this project, so there are no drawings (not that they’re really needed for something like this), but here are some notes I found:

Rod:

- Diameter: 0.5"

- Length: 2.436"

- Bottom thread length: 0.375"

- Top thread length: 0.622"

- Threads: M10x1.5 (turn to down to 0.388" dia for threading)

- Mini Lathe gears for threading (assuming you have an imperial leadscrew): A:40 B:50 C:65 D:55

Bottom piece:

- Material: 1.5" x 0.375" hot rolled flat steel bar

- Length: 2.5"

- Width (after machining surfaces): 1.480"

- Width to fit in lathe bed gap: 0.970"