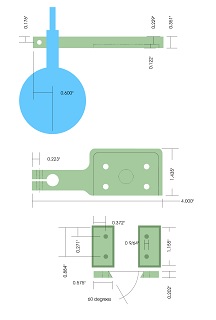

Dial Indicator Holder for Quick Change Toolpost

I made this dial indicator holder for my lathe’s A2Z quick change toolpost because I wanted a fast and convenient way of centering work in the four jaw chuck and I thought this would be a bit faster than messing with a general purpose magnetic indicator base.

I wanted to make it out of a scrap piece of aluminum that I had lying around and I needed to perform a boring operation to fit the shaft of the dial indicator, so I had to make sure the overall dimensions of the part were small enough so I could mount it on the faceplate of the lathe for boring.

The finished dial indicator holder. It has a ledge at the top end of the dovetail

channel that serves as a stop against the top of the tool post to set the height of the dial

indicator so it’s on center with the lathe axis.

I didn’t have a dovetail cutter, so I decided to make the dovetails as

seperate pieces that get bolted to the main body of the holder. I cut the 60 degree dovetail

angle by mounting it in the mill vise and tilting the mill column over.